How does a Vibration Absorber work?

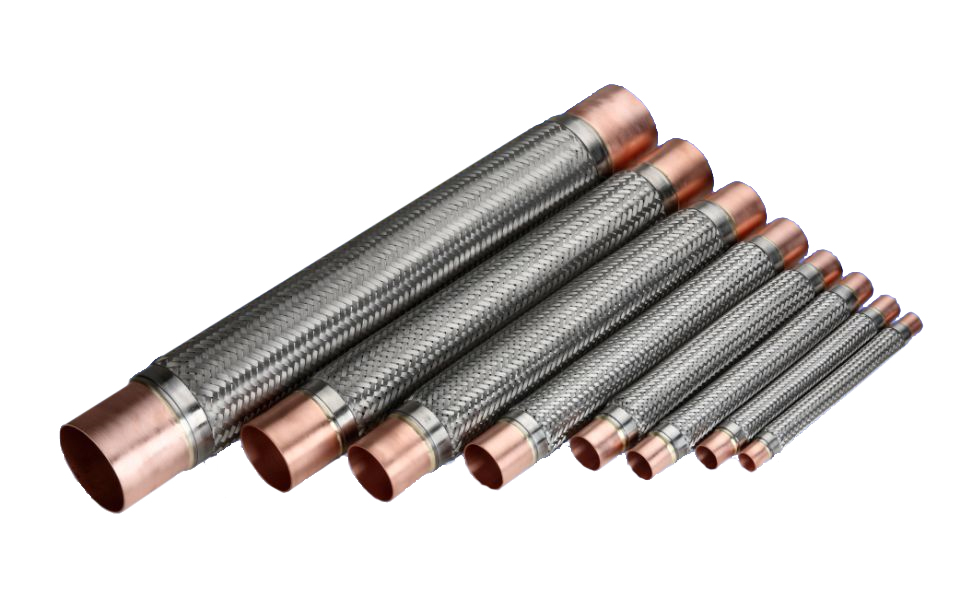

Vibration Absorbers are installed on commercial refrigerating systems and on civil and industrial air conditioning systems with the objective of eliminating the transmission of compressors vibrations to the refrigerating system pipes. Each unit is contructed of a deep pitch corrugated stainless steel hose, covered with a stainless steel braid for superior strength. The hose and braid are reinforced by ferrules at each end and connected to female copper tube ends by a high temperature braze alloy.

Each Vibration absorber is completely pressure and vacuum tested using an advanced helium and hydrogen leak detection

devices. All units are carefully cleaned, dehydrated and sealed in plastic bag and packed into individual box after final inspection and it keeps dry and clean status to prevent dusts or rust.

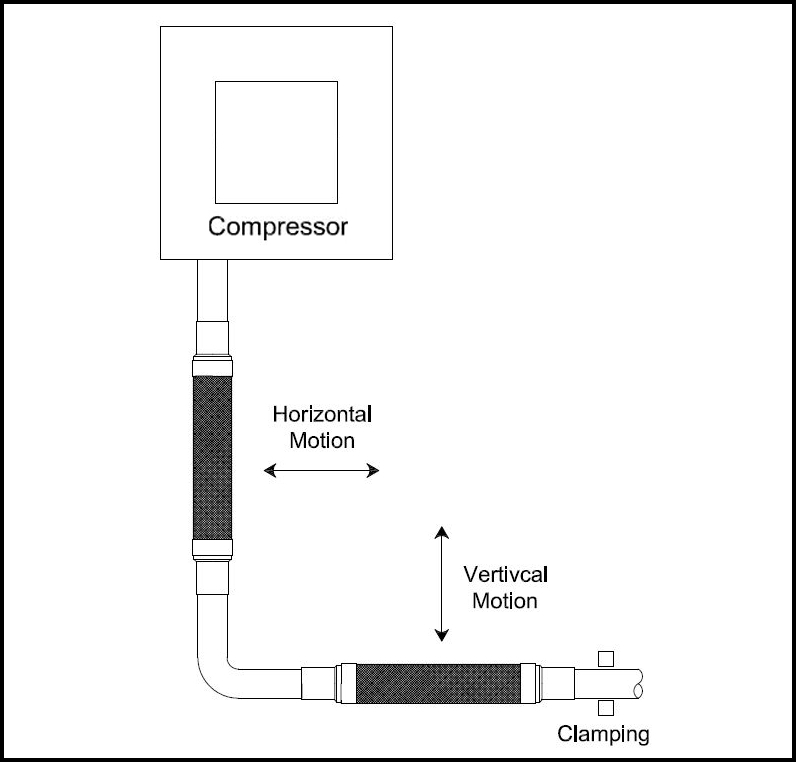

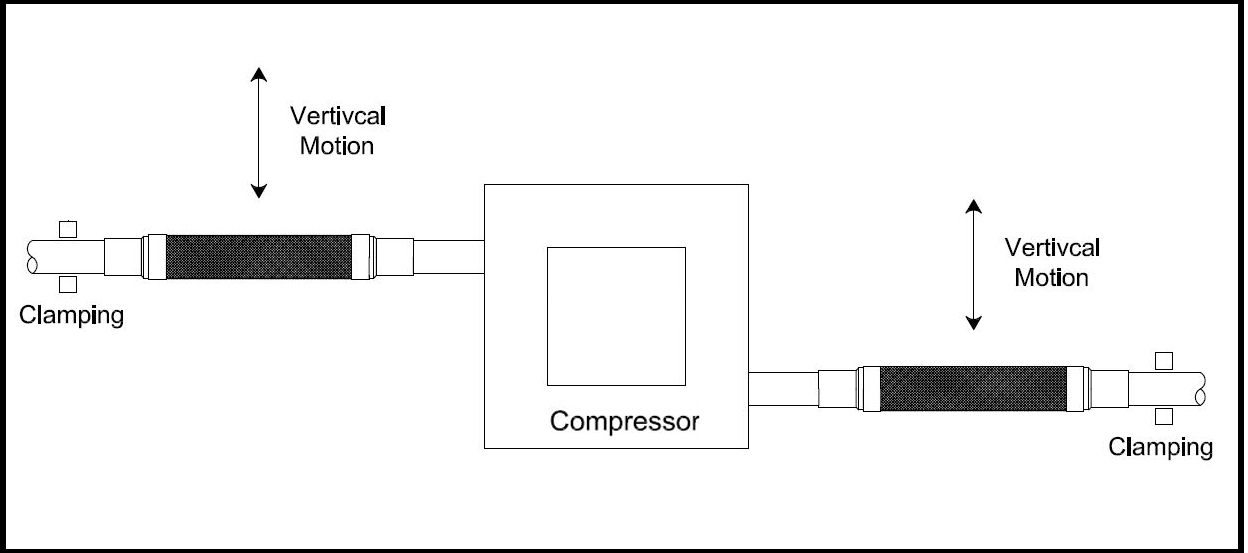

The Vibration Absorber should be fitted as close to the compressor as possible and must be installed in a straight line. Vibration Absorbers are not designed to compensate for pipe-work misalignment. Care should be taken to allow sufficient space for the vibration absorber to avoid static compression or tension, after brazing in place. Vibration Absorbers are not designed to absorb axial or torsional stress. For optimum absorption of vibration, the refrigerant line should be anchored at the end of the vibration absorber furthest from the vibration source.

Copper connection Vibration Absorbers are used with the following ASHRAE 34:2019 refrigerants, Class A1:

HCFC (R22)

HFC (R134a, R404A, R407C, R410A, R507)

HFO (R1234ze)

HFO + HFC (R448A,R449A,R450A,R452A,R513A,R515A,R515B)

Working pressure is 45 bar

304 stainless steel Vibration Absorbers are used with refrigerant R717(NH3), R744(CO2). Working pressure is 60 bar.